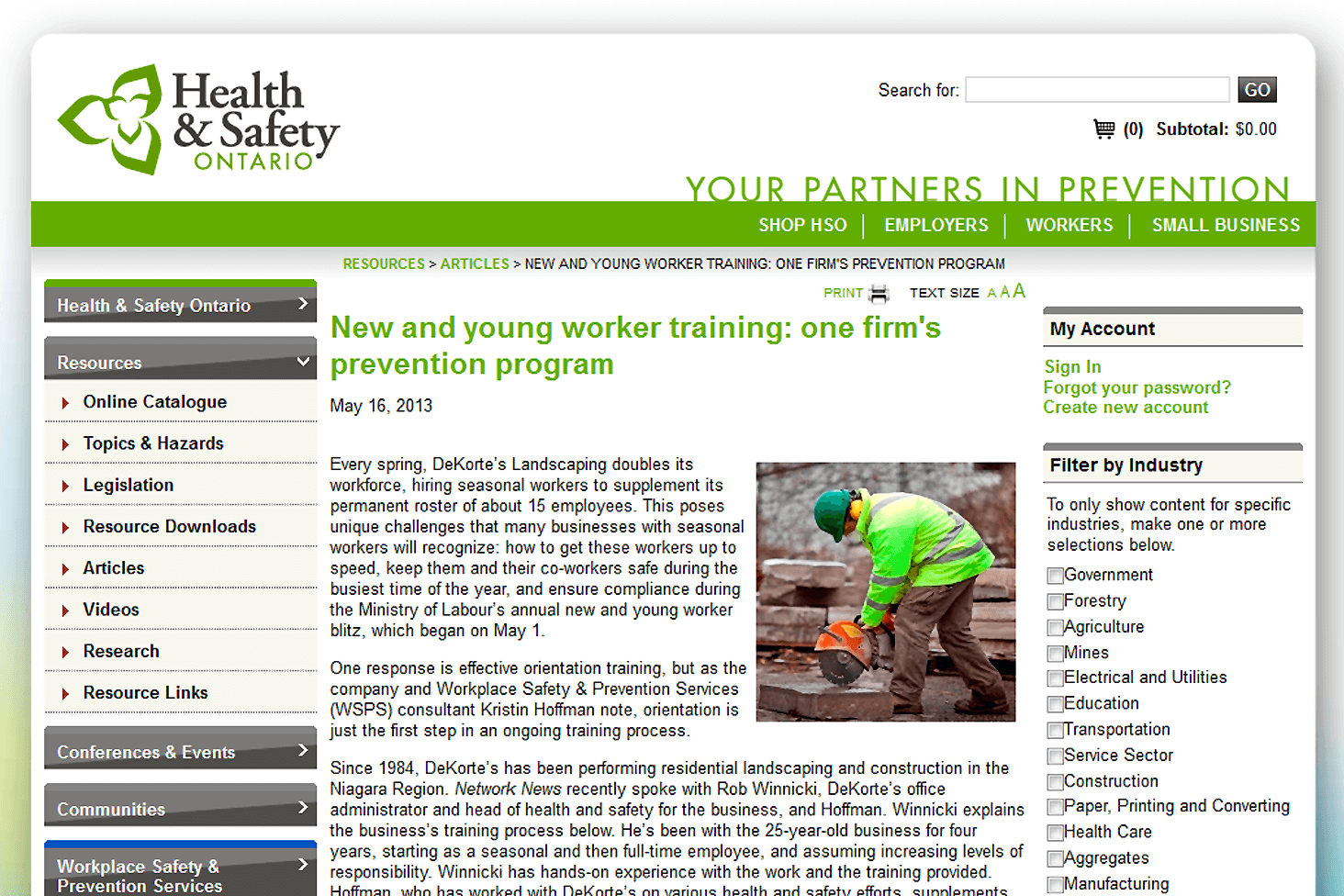

Landscape Ontario member DeKorte’s Landscaping in Fenwick was highlighted by Workplace Safety and Prevention Services (WSPS) as an example of preparing staff for a season of safe employment.

In an article that appeared in the WSPS’ Network News, DeKorte’s office administrator Rob Winnicki, who also serves as head of health and safety for the business, was interviewed.

“Every March before we kick off the season we have an almost full-day orientation meeting,” said Winnicki. Among the topics he listed being covered were injury prevention, emergency response, Workplace Hazardous Materials Information System (WHMIS), company policies and procedures, Accessibility for Ontarians with Disabilities Act (AODA) requirements, customer service and Ministry of Transportation/Ministry of Labour requirements.

As with the general rule for landscape companies, DeKorte’s Landscaping doubles its workforce each spring with seasonal workers supplementing its permanent roster of about 15 employees. Those seasonal workers need to be brought up to speed to keep them and their co-workers safe during the busiest time of the year. The orientation process also ensures compliance during the Ministry of Labour’s annual new and young worker blitz, which began the first of May.

DeKorte’s has been in business in the Niagara Region since 1984, and a member of Landscape Ontario since 1988.

Kristen Hoffman of WSPS, who has assisted DeKorte’s on various health and safety efforts, provided her perspective as a consultant. “All employees participate, and everyone receives an employee handbook. It contains the roles and responsibilities of all workplace parties — the first item on the orientation agenda. The handbook also contains policies and procedures, such as appropriate workplace behaviour (part of our violence and harassment prevention training), use of social media, confidentiality, and other topics. While health and safety is not the sole topic of the orientation meeting, it’s a major component. The goal is to encourage safe, responsible behaviour in all respects.”

In the article, Hoffman describes the orientation training as thorough. She is quoted, “The stronger your first step, the greater success you’ll have with all your subsequent training. It’s an opportunity for new workers to meet and greet other employees.”

Winnicki outlined the company’s procedure. “In addition to orientation training, all new employees receive tool training. The foremen take their crew around the shop and the tool trucks,” he said. The safe operating procedure for each tool is demonstrated on power saws and saw cutters. The foremen also teach employees how to work safely around machinery such as bobcats and excavators.

At DeKorte’s each morning, new workers are assigned a truck buddy who helps them load and unload their truck, and complete job tasks.

Once a month, the foremen also deliver toolbox talks on topics such as upcoming weather, jobsite settings (working safely on the face of the Niagara Escarpment or other slopes), and general housekeeping issues to keep all employees on the same page. “These talks allow foremen to reinforce key safety messages, provide refresher training, and check on workers’ comfort levels with their assigned tasks. Employees know they can ask questions any time, and refuse work they believe to be unsafe. We make it clear to them that prevention is a priority. If something were to go wrong, then it costs in many ways,” said Winnicki.

The company’s health and safety official continued, “Everybody works together as a team, including the supervisor. This person is performing the same tasks with the rest of the crew. It’s much more beneficial this way, instead of having everybody doing something different. From a safety perspective, the supervisor can see and understand any challenges that an employee might encounter. There are a lot of tools to use and skills for new employees to acquire, so the foremen conduct lots of demonstrations and supervise hands-on learning.”

Kristen Hoffman said she sees much strength in DeKorte’s approach to health and safety. Some examples listed in the article include:

Investing in health and safety

DeKorte’s has always taken health and safety seriously, but as the business grew, the owners felt they needed a more robust health and safety program. They understand that health and safety goes hand-in-hand with efficiency, productivity and customer service. One is not more important than the other. Starting in March 2012, WSPS conducted a hazard assessment.

The assessment identified and prioritized office, shop, yard, and offsite activities that could cause some type of issue, whether injury, illness or property damage. From this were developed safe operating procedures and sections on the joint health and safety committee, return to work, and violence and harassment prevention. The program also contains HR elements, such as how to conduct performance reviews, and what to consider when going through a review with an employee.

Delivering orientation training

At DeKorte’s, this training takes place in March. One of the biggest challenges for businesses that employ seasonal workers is finding the time to deliver comprehensive orientation training. Many employers have a narrow window in which they can hire workers, train them, and get them onto the floor. But orientation is a worthwhile investment because it helps establish a standard of performance before that first interaction with co-workers and customers. Once the season starts, it’s hard to pull people off the site for training.

Training for everybody, not just new workers

This ensures everyone has the same understanding of their roles and responsibilities, as well as the employer’s health and safety policy, practices, and performance expectations. It also helps establish a team environment in which everyone is working toward the same goals.

Pertinent information

Many businesses provide some sort of print material that they review with new employees. This can serve as an ongoing reference. DeKorte’s distributes an employee handbook to all participants during orientation training, and goes through it with them. The handbook contains everything an employee needs to know from a health and safety and human resources perspective. DeKorte’s also keeps a copy of the handbook in a binder, along with related forms — hazard reporting, first aid treatment — and required postings, such as the Occupational Health and Safety Act, in each of its trucks. This is a useful practice for any business with employees working offsite.”

Continuous training and coaching

Orientation is just the start, as Rob Winnicki explains. Ongoing efforts keep the training fresh, reinforce key messages, and encourage employees to keep health and safety top of mind.

Be proactive

Proactively implementing health and safety program elements instead of reacting to an order or injury is much easier and more efficient. You’re not putting out fires. Taking your time and stepping back to identify the issues allows you to address them proactively through programs and training before issues arise.

Hoffman concluded by stating, “DeKorte’s has a good system in place.” The WSPS article may be found at http://bit.ly/12RF9CH.