April 1, 2014

Three fears to cast off in 2014

BY MARK BRADLEYFrom a very young age, fear has held us all back from doing so many things we now wished we’d done a lot earlier. Whether it was holding your head underwater, riding your first bike, asking your first girl out, flying on a plane, or going off on your own to start your business, we’ve all had fears that have held us back from doing things that, looking back, weren’t so bad at all. You probably wish you’d done most of these earlier, or more often. In that spirit, let’s turn the spotlight on some fears that will hold your business back in 2014.

Fear of paying higher wages

This isn’t just a company problem, this is an industry problem. The green industry has always been one of the lowest-paying trades, and that continues today. With low wages and seasonal highs and lows in hours, it’s no wonder it’s so hard for us to attract talent. And without talent, it’s no wonder many owners still find their hands pulling every string in their business. Could it be any different if you had better foremen running your crews?

Assume for a few minutes that you did raise your hourly rate for foremen, in an effort to attract better, more responsible talent. Even imagine a big raise… try $5/hr. In a 2,000-hour season, that five-dollar raise will cost you $10,000 more in wages and approximately another $1,500 in payroll taxes and deductions. Total cost: $11,500.

Next, assume that foreman’s skill and talent could increase the crew’s productivity by just 10 per cent. A three-person crew generating $300,000 in annual production would jump up to $330,000. I don’t believe that’s being overly optimistic; I believe it’s a conservative bet.

If you did $30,000 more work, you’d need to spend more on materials, but your equipment costs and your overhead costs wouldn’t need to change at all.

If we look at the math behind this example, our sales increase by 10 per cent. Wage costs increase due to the wages for the foreman, and material costs increase due to the 10 per cent more work being done, but no other costs need to change. If this example played out in reality, you could expect an increase of net profit of $8,500 per crew. If you had three crews, that’s over $25,000 added to your bottom line.

Increasing wages

Sales revenue + $30,000

Wage expenses - $11,500

Equipment expenses N/C

Material expenses - $10,000

Overhead expenses N/C

Net profit + $8,500

So ask yourself: Are you really taking the safe route by attracting lower-paid talent? Or are you limiting your profit, consuming all kinds of hours of your time, and requiring a higher supervision/management burden because you don’t have the necessary talent in key positions in your company?

Fear of equipment payments

In our industry, the old school wisdom preaches you need to own your own equipment — to run your company without payments — and that’s when you really start to make money. Instead, this logic seems to have created an industry that fails to charge enough to recover the true costs of our equipment. Without payments, equipment is treated as free. And it is, but only if you ignore fuel, maintenance and insurance…. and as long as you never need to replace it.

Instead of fearing the commitment that comes with equipment payments or financing, take a few minutes to really look at the cost of doing work without being properly equipped.

Sharing equipment between sites is a waste of time! While transporting the equipment back and forth, the driver could, and should, be working on billable production work. The cost of every hour spent transporting equipment is about $50 (or the amount you charge per hour), plus the materials an employee could also be installing in those hours.

If it takes three crew members one hour to move material from the truck in the front to the backyard, you’ve spent three man-hours moving material that could have been done in mere minutes with a skid steer. At $50 per hour of lost productive time, and no materials installed during that time either, this represents a cost of approximately $300 in lost billable opportunity (productive time).

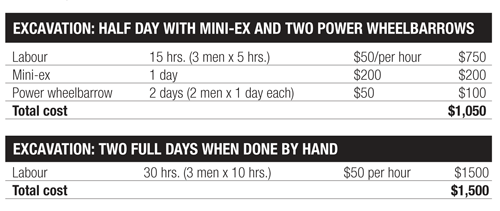

You’re losing out on jobs! Crews equipped with the proper equipment can complete tasks faster. A backyard excavated with a mini-ex and two power wheelbarrows can be done in less than a quarter of the time when compared to a crew without equipment.

You’re losing out on jobs! Crews equipped with the proper equipment can complete tasks faster. A backyard excavated with a mini-ex and two power wheelbarrows can be done in less than a quarter of the time when compared to a crew without equipment.The benefits are clear: The work could be done for 33 per cent less cost, which will reduce my price on the bid.

The crew who finished in half a day gains a full day-and-a-half of production opportunity when compared to the ‘by hand’ crew. By the time the second crew finishes its excavation, the first crew might just be finished with the entire job and already on the next one. Equipment will greatly increase your sales capacity, or opportunity to produce more work.

Fear of being expensive

One of the biggest concerns in our industry is lowball competition. These are the companies that price their work at a loss because they don’t know what they’re doing. So, in some twisted effort to keep our costs competitive with these companies, we’re afraid to take on the costs of better staff, better equipment, and better technology. This way, we assume, we can still be competitive.

FACT: A recent Unilock study followed a series of leads from first contact right through to the final invoice. In 80 per cent of the cases, the customer did not select the lowest-priced job.

If you’ve got a fear of getting outpriced, spend some time looking at other markets. There are thousands of companies that get outpriced, and achieve tremendous success despite this fact. Starbucks, Honda, Coach, Lululemon, Nike, Ritz-Carlton, Oakley, DeWalt, 3M… all these companies thrive in competitive markets, throughout recessions, and despite hundreds of cheaper options, they don’t worry about being low-priced. Why? They market themselves as a premium brand. Think about ways you could improve your company’s image to reassure your customers that they’re getting premium service:

Your website; your business cards, your logo, your stationery; the way you dress for sales presentations;

the look and feel of your brochures and marketing material; your proposal package, designs,

and sales presentations; the age and cleanliness of your trucks and equipment; and the organization

and cleanliness of your jobsites

Good marketing can beat cheap pricing. Don’t fear being more expensive. Instead, be afraid of looking anything less than your best. If you want to charge a premium, let your marketing give your customers the reassurance that you’re going to deliver a premium in return.

Just like the first time you dunked your head underwater, or the very first time you asked for someone’s phone number, fear often prevents us from doing things that would make our lives better, easier, and more enjoyable. Running our business is no different. From the first time you asked for a sale, to the time you watched your first foreman drive your truck and equipment down the road independently, we’ve all been afraid of changes that obviously will make our business better. Now, wiser and more experienced, just take that same wisdom and apply it to some of the biggest challenges you’re facing this year. You won’t regret it.

Mark Bradley is president of TBG Landscape and the Landscape Management Network (LMN), in Ontario.