March 14, 2024

Mission: precision

How RTK technology can help landscape trades pros hit the mark when it comes to turf care

BY KALI PEARSON

While most trade show exhibitors are quite happy to walk away with a few solid leads and a pile of badge scans, Steve Uljua, senior outdoor robotics manager at Kress is just happy no one is yelling at him anymore.

As part of the training team for Kress’ robotics division (and before Kress, Husqvarna), Uljua has been in the robotics game since 1998 and can remember when he used to get nothing but shade from landscapers on the trade show floor.

“There were years and years of landscapers coming by the booth, literally screaming and hollering,” he said. “They said that robotics were taking away business and making landscapers a thing of the past.”

These days, it’s a much different story. Robotic mowers are gaining wider acceptance in the market — particularly for municipalities and large commercial properties.

Thanks to strides in technology, robotic mowers are far more accurate. Batteries last longer. Many municipalities are cracking down on noise pollution and emissions. Labour is hard to find — and higher fuel costs makes sending crews to remote locations costly. Put it all together and robotic mowers are having a real moment.

The new robotics

While robotic mowers themselves aren’t new, they haven’t always delivered professional-quality results. Integrating them into the maintenance workflow was clunky. First a wire would need to be stapled or buried around the perimeter of the property. Then the unit would then rove (rather aimlessly) until it hit an obstacle or ran out of battery. Much like first-generation Roombas, they were novel… but not exactly effective.

Today, manufacturers including Kress, Husqvarna and Green Machines are offering robotic mowers that leverage Real-Time Kinematic positioning (RTK) technology, with the promise that they can mow almost as well as (or better than) your average human.

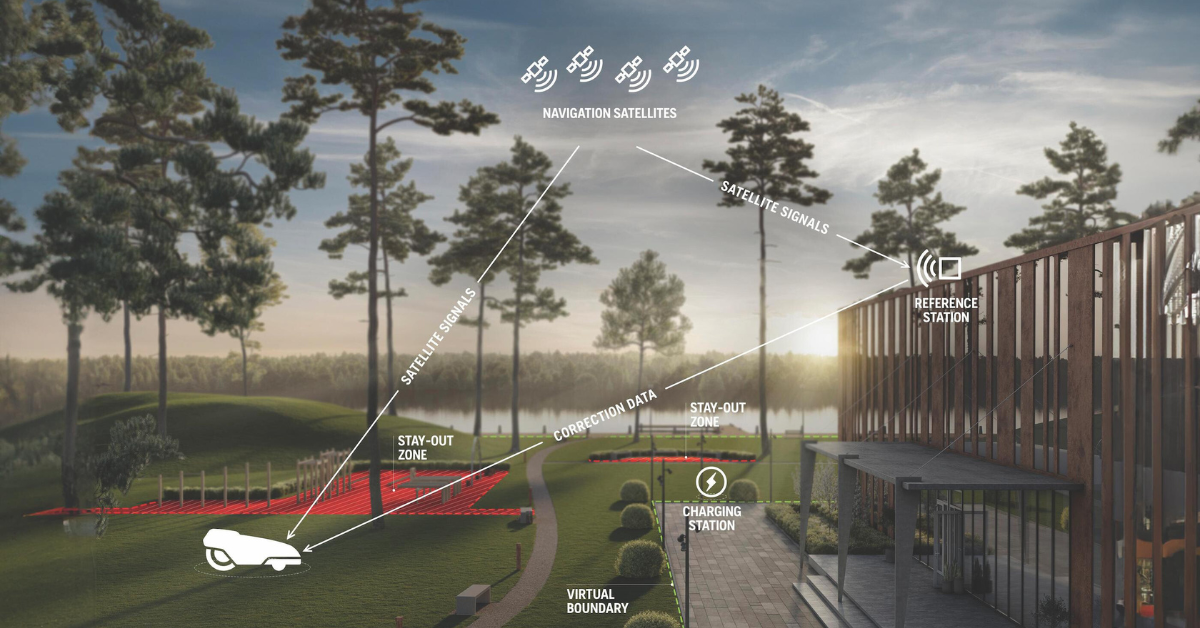

Put very simply, RTK works a lot like the GPS found in navigation systems… but better. While GPS technology provides accuracy within about a metre, RTK layers in surveying data that delivers greater precision. The satellite and the mower are both moving objects and with RTK, a fixed antenna is installed to determine the exact positioning of the mower. "This technique provides centimetre-level accuracy in seconds,” said Courtney Beall, senior brand manager, Green Space Professionals, at Husqvarna Group, which has long been a key player in robotics.

RTK technology was initially developed for military applications. Next, surveyors and large-scale industrial farming operations adopted it. Most recently, automotive companies have used it to develop autonomous vehicles. “With Tesla and all these people who are working with that technology, it just kept driving the price down,” said Uljua.

Of course “down” is relative — and with mowers costing from $2,300 for a smaller unit to over $13,000 for machines capable of moving up to nine acres, no one is saying entire fleets of lawnmowers will be replaced immediately. But Paul Ronan, executive director of Parks Ontario, says that these machines are definitely “here to stay” — especially when it comes to areas that are remote or need a very specific cut to be maintained daily.

Ronan cites a cricket field in Kitchener, Ont. “It’s a bit of a pain to get to, and players wanted a very specific height of cut maintained every other day,” he said. The City of Kitchener purchased one of these new generation robotic mowers — and Ronan says it works brilliantly.

“The quality of the cut is very good. What I’m seeing is that they are very dependable and don’t require much maintenance,” says Ronan. “Yes, you do need to sharpen the blades, but the big thing it saves you on, is the manpower.”

Speaking of low maintenance, these mowers can be tracked live via phone or computer — and today's units will send an error message your way if it experiences a breakdown or malfunction. The machines can even be programmed to drive right onto their charging unit at the end of the day. “We see people building little ‘dog houses’ for them,” says Ronan. If anyone tries to pick one up, it shrieks like a banshee (and even intrepid thieves will find they can only be operated with a PIN).

Right now Ronan suspects most of the early adopters are municipalities and landscapers servicing more remote properties where the terrain is predictable, but he believes greater adoption will grow quickly now that technology is living up to its promise.

More mowing, less environmental impact

Uljua also mentions that daily or almost daily mowing has been demonstrated to eliminate or reduce the need for overwatering and fertilizing — great news for our waterways and for those wishing to leave a lighter footprint. Studies from University of Kentucky and University of Georgia have demonstrated that by constantly trimming grass a little bit at a time, the lawn becomes healthier — and the small pieces of cut grass decompose quickly, putting nutrients right back into the soil. In the same studies it was determined that these mowers resulted in about 35 percent less water used to keep a beautiful lawn, depending on where you are in North America, said Uljua.

This is obviously great news for those managing very large or remote sites, but what about landscape crews serving smaller commercial or residential sites?

Ronan says there is still some resistance in this market. After all, why would a consumer continue to pay a crew if the mower will do the work “for free”? He says there’s also a potential downside for unionized companies, which have to disclose use of robotics and demonstrate that they are not taking away existing jobs.

“The reality, though, is that I have not heard of a single example of this yet,” said Ronan. “Municipalities and companies are so short-staffed they are far more likely to be trying to hire people than trying to fire them.”

Uljua is seeing a similar story on the trade show floor. “Now, landscapers are lining up to ask questions,” he said. “They understand that the robots are not going to trim hedges, they’re not gonna fertilize, they're not gonna do the edging and the blowing and all the other work that needs to be done,” he said. “They can cut checkerboards, stripes going north, stripes going sound, stripes going left or right, but they just mow grass.”

And for those of us hoping for a little robot help in other sectors, Uljua is already excited about what might be coming next — from larger mowers to snow ploughs. “Affordable RTK has opened up the floodgates,” he said. “I'm glad I've been in business long enough to see both ends of the spectrum — and I really do love going to shows more, now that people see the positives.”